Test based on BS EN ISO 1452-3

| Item | Requirement | |

Exterior | The surface should be smooth and flat, no cracks, bubbles, peeling, obvious impurities, serious cold spots, uneven color, decomposition and discoloration are not allowed | ||

Size | Meet the requirements of BS 4346, Clause 3.3, Table 1 | ||

Oven test | Test temperature: test time e≤3mm3mm<e≤10mm10mm<e≤20mm20mm<e≤30mm30mm<e≤40mme>40mm | 150±2℃ 15min30min60min140min220min240min | |

No serious bubbles, delamination or weld line cracks are required | |||

Vika | ≥74℃ | ||

Internal pressure | dn<160mm, 20℃, pressure 4.2xPN, 1hdn≥160mm, 20℃, pressure 3.36xPN, 1h, no cracks are required | ||

Marking | Comply with 13.2 in the BS EN ISO 1452-3:2009 standard, and require standard number, trademark, size, raw material, PN value, use W/P | ||

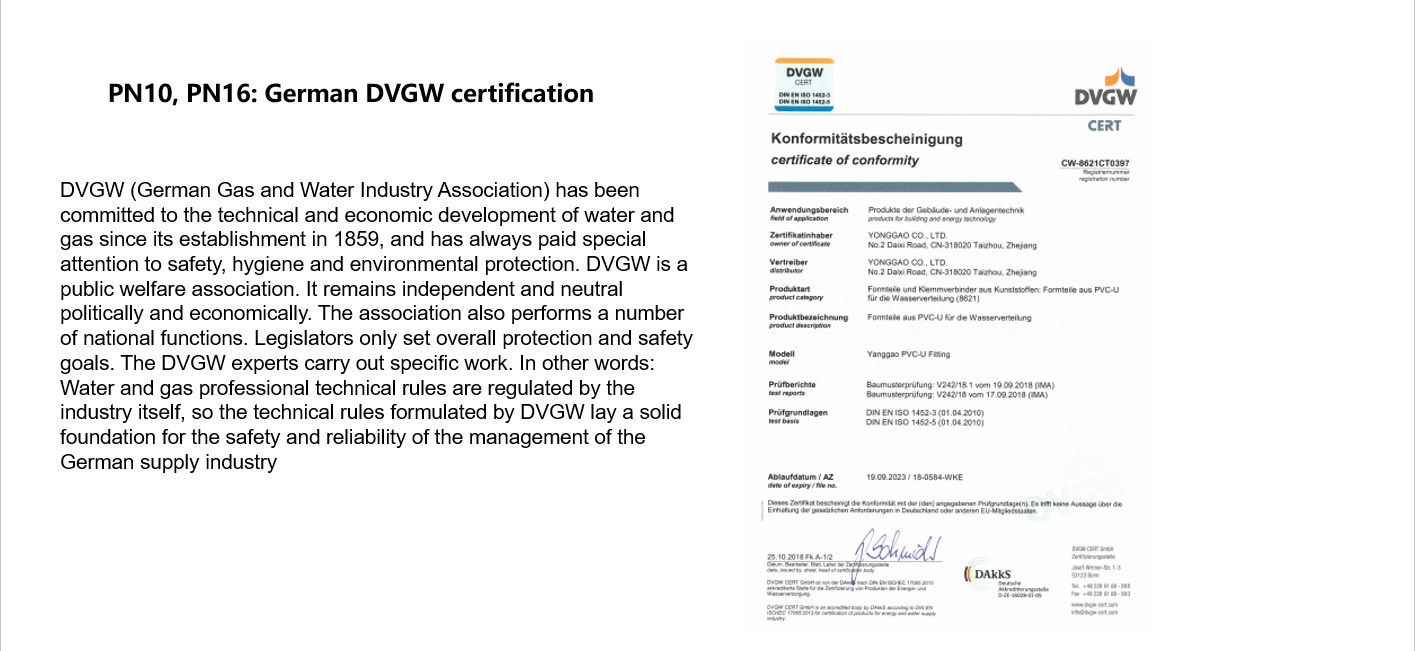

Tests: | Requirement/test standard:W534 | Initial type test | Self-monitoring | Third-party control |

Hygiene | Fitting has to fulfil KTW-recommendations | Yes | Documentation | 1 x per year |

Material acc. work sheet W 270 and organoleptic test following KTW-recommendations | Yes | Documentation | check of doc | |

Raw material (PP-R) | Long-term behaviour acc. ISO 9080 and table 7 | Normally by test report | No | No |

Melt mass-flow rate (MFR) 190/5 < 0.2 g/10 min( | Yes | 1 x per week | 2 x per year | |

Hydrostatic pressure tests | At 20°C, 1 hour, 6.40MPa , no burst ,no leakage20°C。At 95°C, 1000 hour, 1.40MPa , no burst ,no leakage95°C。 | Yes | 1 x per month 20°C/6.40 MPa /≥1h | 2 x per year |

Dimension and tolerance | Acc. to the tables of DIN 16962and EN 10226-1 | Yes | Continuously | 2 x per year |

Tightness under pressure cycling | Tight after 10,000 cycles (30 cycles/min) at 20 °C between 1 and 25 bar | Yes | No | No |

Thermal cycling | Tight after 5,000 cycles (1 cycle = 30 min) between 20 °C and 93 °C,10 bar internal pressure10 bar | Yes | No | No |

Bending | Tight under bending with 8xd at 18 °C / 15 bar/ ≥ 1 h18 °C | Yes | No | No |

Marking | Min.: DVGW and reg. no., PP-R, pipe-Ø, thread- Ø system name | Yes | Continuously | 2 x per year |

Homogeneity | ≤ 0.02 mm² / evaluation on microtome with 10 μm, scale of enlargement 75-100, determined surface min. 100 mm² | Yes | 1 x per week | 2 x per year |