Insulation electrical pipe inspection items and basis | ||||

Insulation electrical pipe for construction | Item | Requirement | Detection method | Frequency of inspection |

Exterior | smooth | Visual inspection | 3 times/shift | |

Minimum wall thickness | Not less than the standard in Table 2 of JG/T 3050-1998 | Vernier caliper | 3 times/shift | |

Maximum outer diameter | Rubric can pass by weight | Gauges | 1 time/shift | |

Minimum outer diameter | The rubric cannot pass by weight | Gauges | 1 time/shift | |

Minimum inner diameter | Rubric can pass by weight | Gauges | 1 time/shift | |

Compressive performance | Change rate of outer diameter at 1min load≤25% | Universal testing machine | 1 time/day | |

Change rate of outer diameter when unloading for 1min≤10% | Universal testing machine | 1 time/day | ||

Folding performance | When the room temperature is ≥15℃, hold hands tightly and bend slowly at a distance of 1m without brittle fracture | By hands | 1 time/shift | |

When the room temperature is less than 15℃, the tube is inserted into the spring to bend quickly by hand without brittle fracture | ||||

Bending performance | No visible cracks | Bending test machine | 1 time/day | |

Impact performance | At least 10 of the 12 specimens are not broken or cracked | Impact testing machine | 1 time/day | |

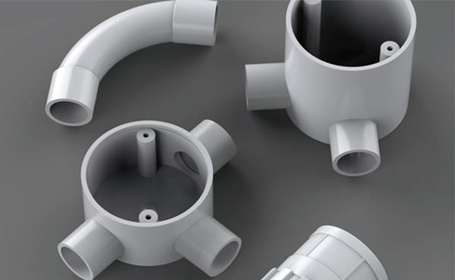

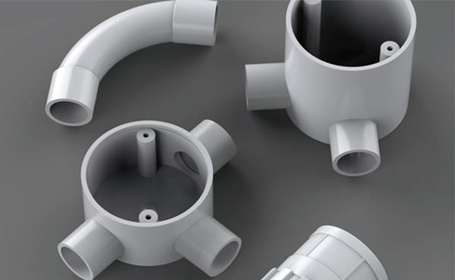

PVC electrical accessories testing items and basis | ||||

PVC electrical accessories | Item | Requirement | Detection method | Frequency of inspection |

Exterior | Smooth without cracks | Visual inspection | 1st piece/shift | |

Size | Meet the company's drawing requirements | Measured with calipers with an accuracy of 0.01mm | 1st piece/shift | |

Drop performance | No cracking or broken | According to JG/T3050-1998 standard 6.8.1 "Sleeve and accessories drop performance" test | 1st piece/shift | |

Density | Internal control density requirements | GB/T1033.1-2008 standard test | 1st piece/shift | |