Test | Requirements |

Size detection | Socket size: plug gauge or caliper Thread detection: thread gauge |

Anti-fatigue test | Test according to ISO8659, 2500 cycles, no leakage of components. During the test, the inside of the sample is filled with water, the outside is air, the internal pressure is the nominal pressure, and the test is performed at room temperature at a flow rate of (1±0.2) m/s |

Vicat softening temperature | ≥74℃ |

Shell internal pressure test | No leakage, no rupture |

external assessment | Product appearance: the surface is smooth, tidy, flawless, and the product is clearly marked. Gate: smooth and free of burrs |

Block valve sealing performance test | Air pressure detection in two states of opening and closing(1/2"-2" 6KGS water pressure hold for 15 seconds, 2" or more 8KGS water pressure hold for 15 seconds. |

test | Minimum test time | test pressure | Test temperature | Test medium | |

internal | external | ||||

| 60 | 0.05 | 20±2 | air | water |

DN≤200mm,15 | 1.1xPNa | water b | air | ||

DN>200mm,30 | |||||

| DN≤200mm,15 | 1.1xPNa | water b | air | |

DN>200mm,30 | |||||

a. The maximum test pressure is (PN+0.5)Mpa | |||||

Tests | Requirement/test standard | Initial type test | Self-monitoring | Third-party control |

UV resistance | Acc. to AS 3558.5,the plastic components should not crack, craze or show any other failures. | Yes | No | At any any change in materials specification |

Elastomeric materials | The materials used for seals or gaskets shall comply with AS 1646.1 and AS1646.2 | Yes | No | At any any change in materials specification |

End connector | The connection ends shall be tested and verified according to AS 1477 Table 5.1 & Table 5.2 | Yes | Once per batch | At any change in the design |

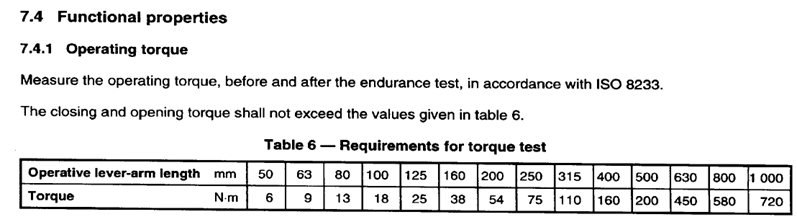

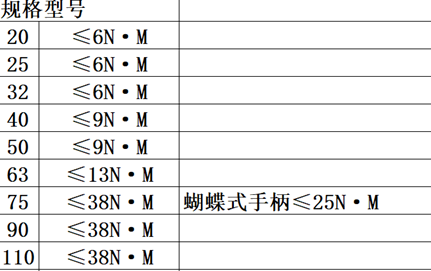

Torque test for body assembly | When tested in accordance with Appendix B, the valve shall show no signs of splitting, Cracking, distortion or thread damage | Yes | No | At ant change in design or manufacturing process |